Process and Methodology of Mix Media Dyeing

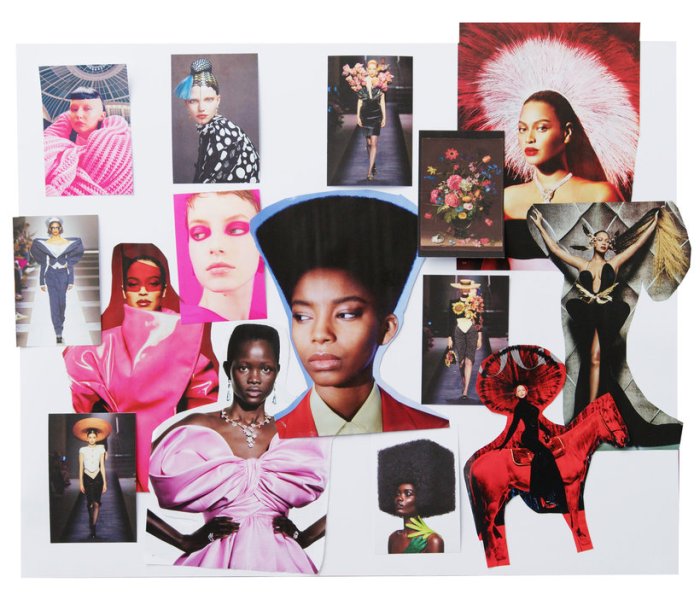

Contoh desain busana hasil pewarnaan mix media – Mix media dyeing offers a versatile approach to textile design, allowing for the combination of various dyeing techniques and materials to achieve unique and complex visual effects. This process involves a careful consideration of fabric pre-treatment, dye application methods, and post-treatment procedures to ensure both the aesthetic and structural integrity of the final garment. The following sections detail the steps involved in creating a sample garment using a chosen mix-media dyeing technique, the importance of pre and post-treatment, and a comparison of different dye application methods.

Step-by-Step Process of Mix Media Dyeing on a Sample Garment

The creation of a garment using mix media dyeing involves a series of carefully orchestrated steps. The following table Artikels a sample process, using shibori resist dyeing combined with screen printing for a specific design effect. Note that this is just one example; the specific steps and materials will vary depending on the chosen techniques and desired outcome.

The vibrant, experimental nature of contoh desain busana hasil pewarnaan mix media, with its bold use of color and texture, ironically highlights the often bland, homogenized aesthetics of mass transit. Consider the stark contrast when you examine the supposedly innovative designs of contoh desain bus diluar negeri terbaru ; the limitations of practicality often stifle true artistic expression, leaving contoh desain busana hasil pewarnaan mix media to showcase a far more daring and individualistic approach to design.

| Stage | Action | Materials | Result |

|---|---|---|---|

| Preparation | Pre-wash fabric to remove sizing and impurities. Prepare dye baths according to manufacturer’s instructions. Prepare shibori binding materials (rubber bands, string, etc.) and screen printing stencils. | Cotton fabric, detergent, water, dye powder (e.g., indigo, procion MX), rubber bands, string, screen printing frame, stencil, squeegee | Clean fabric ready for dyeing; dye baths prepared to the correct concentration; shibori and screen printing tools ready. |

| Resist Dyeing (Shibori) | Fold and bind the fabric using chosen shibori technique (e.g., kanoko, itajime). Ensure the fabric is tightly bound to create defined resist patterns. | Fabric, rubber bands, string | Fabric prepared with defined resist areas. |

| Dye Application (Indigo) | Immerse the bound fabric in the indigo dye bath, following manufacturer’s instructions regarding time and temperature. | Indigo dye bath, container, gloves | Fabric dyed with indigo, showing patterns created by the resist. |

| Unbinding and rinsing | Carefully unbind the fabric and rinse thoroughly under cool running water until the water runs clear. | Running water | Revealing the indigo dyed pattern created by the shibori resist. |

| Screen Printing | Position the screen printing stencil onto the fabric and apply dye using a squeegee. | Screen printing stencil, procion MX dye, squeegee | Addition of a secondary design element onto the previously dyed fabric. |

| Post-Treatment | Rinse thoroughly, then wash in cold water with a mild detergent. Allow to air dry. | Water, mild detergent | Clean garment with vibrant and lasting color. |

Importance of Pre-treatment and Post-treatment Processes

Pre-treatment processes, such as washing the fabric to remove sizing agents and impurities, are crucial for ensuring even dye uptake and preventing uneven coloration. Sizing agents can act as a barrier, preventing the dye from penetrating the fibers effectively. Impurities can also interfere with the dyeing process, leading to blotchy or uneven results. Post-treatment, which involves rinsing and washing the dyed fabric, helps remove excess dye and fix the color, ensuring the vibrancy and longevity of the dyed garment.

This also helps prevent color bleeding or fading over time.

Comparison of Dye Application Methods

Screen printing, tie-dye, and resist dyeing represent distinct methods of applying dyes to fabric, each with its own advantages and limitations. Screen printing offers precise control over design and allows for the creation of intricate patterns. However, it requires specialized equipment and is less suitable for large-scale production. Tie-dye is a more improvisational technique, producing organic and often unpredictable results.

It’s relatively simple to execute and requires minimal equipment. Resist dyeing, encompassing techniques like shibori, utilizes various methods to prevent dye from reaching certain areas of the fabric, resulting in striking patterns. This method is highly versatile but requires a level of skill and patience to master. The choice of method depends on the desired design aesthetic, the scale of production, and the level of technical skill.

Exploring Different Fabric Types and their Interactions with Dyes

The success of mix-media dyeing hinges significantly on the careful selection of fabrics. Different fibers possess unique chemical structures and physical properties that dictate their affinity for various dyes, ultimately influencing the final aesthetic and durability of the dyed garment. Understanding these interactions is crucial for achieving predictable and desirable results. This section will explore the suitability of various fabric types for mix-media dyeing, highlighting their unique characteristics and potential challenges.

The choice of fabric profoundly impacts the outcome of the dyeing process. Natural fibers like silk, cotton, and linen, each exhibit distinct dyeing behaviors due to their inherent molecular structures and porosity. Synthetic fibers, on the other hand, present a different set of challenges and opportunities, requiring specialized dyeing techniques and considerations.

Silk’s Interaction with Dyes

Silk, a luxurious protein fiber, boasts a high affinity for dyes due to its amino acid composition. This allows for vibrant and richly saturated colors. Acid dyes are particularly effective on silk, producing deep, lustrous shades. However, silk’s delicate nature requires gentle handling throughout the dyeing process to prevent damage. Overly aggressive agitation or high temperatures can lead to fiber degradation and uneven dyeing.

Pre-treating silk with a mild detergent to remove sericin (a natural gum coating) can enhance dye uptake and ensure even color distribution. The resulting dyed silk fabric displays a luxurious drape and a subtle sheen, enhancing the overall visual appeal of the garment. The vibrant colors achieved on silk also contribute to a high-end aesthetic, especially when combined with other media in a mix-media approach.

Cotton’s Dyeing Properties

Cotton, a cellulose fiber, is a popular choice for dyeing due to its affordability and absorbency. It readily accepts direct, reactive, and vat dyes, offering a wide range of color possibilities. However, cotton’s cellulose structure can lead to less vibrant colors compared to silk. Pre-mordanting with a substance like alum can improve dye uptake and colorfastness. The even absorption of dyes on cotton leads to a uniform color distribution, suitable for achieving clean lines and bold patterns in mix-media dyeing.

The natural texture of cotton also allows the added media to interact in interesting ways, creating tactile interest in the final product.

Linen’s Response to Dyes

Linen, another cellulose fiber, shares similarities with cotton in terms of dye uptake but possesses a slightly different texture. Its coarser fibers can create a more rustic look after dyeing. Like cotton, pre-mordanting can enhance dye absorption and colorfastness. Linen’s strength allows it to withstand more aggressive dyeing techniques, offering flexibility in the mix-media process. The unique texture of linen, even after dyeing, adds a distinct visual and tactile quality to the garment, contrasting beautifully with smoother fabrics or added media elements.

Challenges in Dyeing Different Fabric Types and their Solutions

Several challenges arise when dyeing different fabrics using mix-media techniques. One common issue is uneven dye distribution, particularly noticeable with fabrics that have varying levels of absorbency. This can be addressed by pre-treating the fabric to ensure uniform moisture absorption. Another challenge is color bleeding or fading, which can be mitigated by using appropriate dyes and employing proper after-treatment methods like washing and fixing.

Finally, the different shrinkage rates of various fabrics can cause distortion in the final garment. Pre-washing fabrics before dyeing can help to minimize this problem. Careful selection of compatible fibers and meticulous attention to detail throughout the dyeing process are crucial for successful outcomes.

Fabric Choice and Final Appearance, Contoh desain busana hasil pewarnaan mix media

The choice of fabric significantly impacts the final appearance and texture of the dyed garment. Silk’s smooth surface and lustrous sheen will yield a luxurious and elegant finish, while cotton’s softer texture creates a more casual feel. Linen’s slightly coarser fibers contribute to a rustic and natural look. The interaction between the fabric’s texture and the applied dyes, along with additional mixed media, creates a unique visual and tactile experience.

For example, a mix-media design using silk dyed with vibrant acid dyes and embellished with metallic leaf will have a very different aesthetic compared to a design using cotton dyed with earth tones and embellished with natural fibers. The choice of fabric should be carefully considered based on the desired aesthetic and the nature of the intended mix-media elements.

Detailed FAQs: Contoh Desain Busana Hasil Pewarnaan Mix Media

What are some common mistakes to avoid when mix-media dyeing?

Common mistakes include improper pre-treatment of fabrics, incorrect dye ratios, and neglecting post-treatment processes like washing and setting. Careful planning and attention to detail are crucial.

How can I achieve specific color combinations using mix-media dyeing?

Experimentation is key! Start by understanding the individual properties of each dye. Layer dyes strategically, using techniques like overdyeing or resist dyeing to achieve complex and unique color blends.

Where can I source high-quality dyes for mix-media textile dyeing?

Specialty art supply stores, online retailers, and some fabric stores carry a range of natural and synthetic dyes. Research different brands and read reviews to find options suitable for your needs.